|

Lock Out Tag Out

Lockout/Tagout (LOTO) Compliance ~ OSHA 1910.147

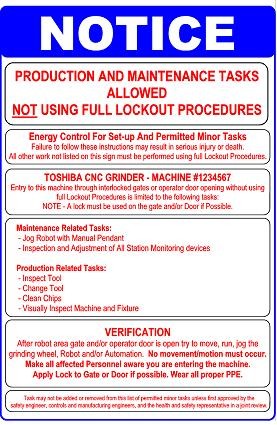

Industrial Signs offers a complete turnkey system for LOTO that includes:

- Signs

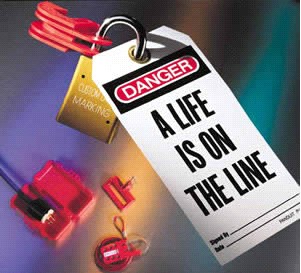

- Tags

- Master Books

- Lockout Centers (Lockout tags, Padlocks, Valve lockouts, Plug lockouts, etc.)

In addition, we offer training and an on-going customer relationship to manage, update and ensure "safety lockout" compliance.

A proper LOTO system is one of the most important parts of a manufacturing facility. Whether used during routine maintenance or in an emergency situation, a clear LOTO procedure generates cost-effectiveness by:

- Ensuring safety of employees

- Protecting and maintaining valuable machinery

- Minimizing expensive production downtime

Lockout/Tagout procedures have also become one of the most common

compliance problems among federal safety inspectors.

Plant safety involves more than just posting a few signs. It is achieved by having visual management solutions in place to prevent injuries and accidents via education and awareness. Regular safety audits, safety training and documentation are key building blocks that are often overlooked. By offering an in-depth audit, combined with effective safety visual aids and proven safety components, Industrial Signs will help you create a safer workplace.

In addition to the creation of machine-specific, graphical LOTO procedures, we can review and/or create a corporate LOTO policy to help establish a firm foundation for your Company’s program. We understand industry-wide best practices and can utilize our knowledge and experience to deliver unsurpassed technical service.

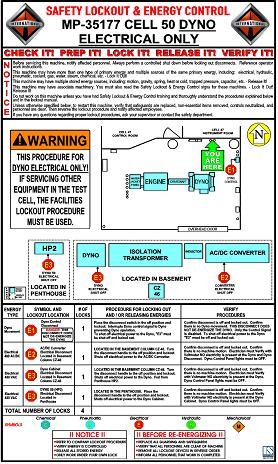

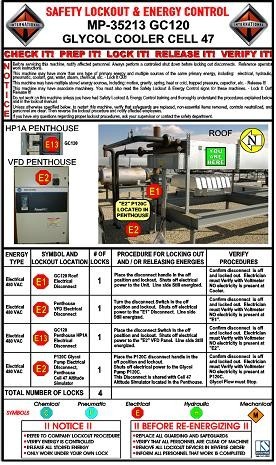

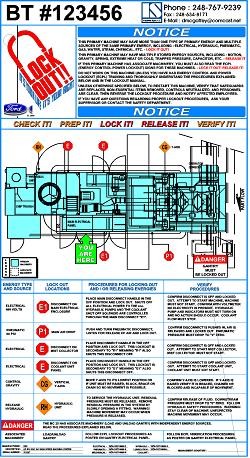

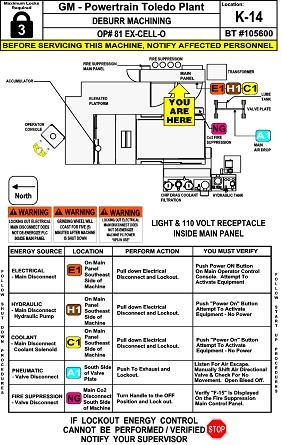

Easy to follow safety procedures are the backbone of any successful manufacturing line. Using the best in digital photography, Industrial Signs creates a graphical LOTO procedure that withstands extreme manufacturing conditions.

Industrial Signs creates graphic procedures that exceed federal regulation CFR 1910.147. We can either help your safety team create comprehensive LOTO procedures or we can simply assist with specific parts of the process. CLICK HERE to contact an Industrial Signs representative today and you'll be on your way to compliance.

Cost of Non-Comformance

The costs of not having a complete, comprehensive, LOTO program can come from four main sources:

- Lost Work Time ~ from the increased time an employee must spend to lock out a machine that does not have a clear, up-to-date LOTO procedure

- Lost Production ~ from machine down time; reducing the time it takes to service a machine can obviously have a significant value

- OSHA Fines ~ which can be another substantial expense; LOTO violations are one of the most often cited OSHA infractions within the manufacturing sector

- Employee Injuries ~ the cost of workplace injuries can be much greater in situations where the employer either failed to provide LOTO procedures and/or failed to properly train employees. In cases where an employer is found negligent in safety procedures, multi-million-dollar lawsuits are not uncommon.

Lean manufacturing today is not just a trend; it’s a necessity to create a competitive advantage. A lean philosophy can easily be incorporated into a LOTO program by consolidating tradesman knowledge, reducing down times and promoting safety.

How We Work

Once contracted, Industrial Signs will perform the following steps to complete the job:

- Meet with You and Your Staff to Discuss the Project

- Develop a List of Machinery and Equipment to Audit.

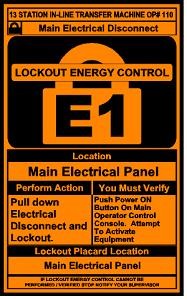

- Audit your facility for all machinery and equipment that have the potential for requiring lockout. During the Audit we will coordinate through your appropriate personnel to locate the equipment, lockout points and procedures to develop the “Lockout placard”.

- We will make preliminary signs and control tags. We will email or print and mail an approval.

- Upon receipt of the approved copy (note: we will make any and all design modifications at no additional cost to you until the sign is approved) we will make any changes and submit a final paper or emailed copy. At this time we will field check the procedures to ensure accuracy.

- Upon your “approval sign off” we will then create the final output in metal. The signs and control tags will come with industrial double-sided tape or holes.

- We will package and ship to your location.

- Once at your location we will be happy to mount the signs (simply peel and stick), or you can easily install.

- Set-up Lockout Training and Procedure Program

We will develop, standardize and document the lockout process for each energy source. We will then identify employees’ levels of involvement in the program; those that are simply made aware, those that are directly affected and those that are expected to perform the lockout procedures.

|

|